- Exclusively only from HAZET

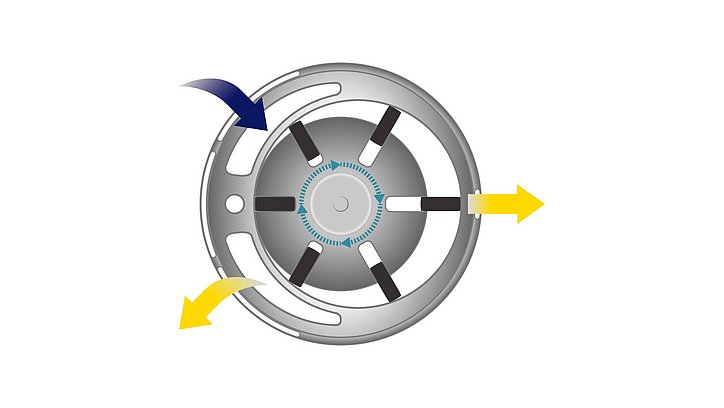

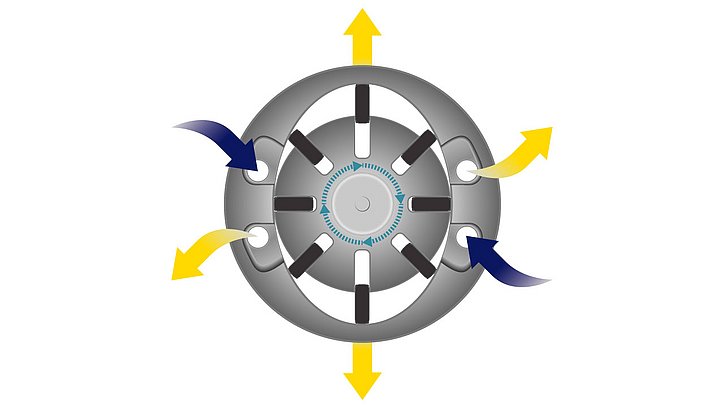

- Maximum efficiency thanks to pioneering "HAZET Twin Turbo technology" enables high torques in a compact design

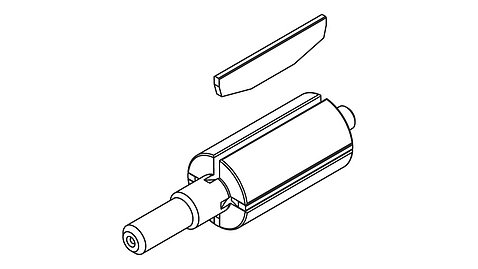

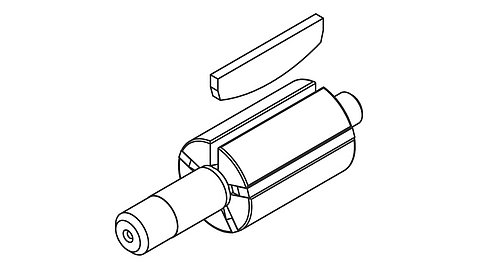

- Innovative 8 blade air motor with 25 % higher impact power ensures maximum torque

- High service life and high efficiency in industrial and automotive applications