From idea to series production

Inspired by new customer requirements, current trends and feedback from the market, we are constantly developing attractive new products and problem solvers. Our innovations are Made in Germany. From the idea for a new product, through development to series production. All of this takes place here in Remscheid.

The focus is always on the highest quality, a clever solution to a problem – ideally in combination with an inspiring benefit! We use high-quality materials for all our products and focus on excellent workmanship for maximum reliability and safety.

This is exactly what is premium and guarantees the durability of HAZET tools. Join us on the journey from the initial idea to series production!

The path of a product

Phase 1: An inspiration – The beginning of our innovation process

In the first phase, the focus is on brainstorming. We find inspiration internally and externally. Among our colleagues, users, customers and partners: From the market.

Because we at HAZET are close to the practice and to our professional users. We are driven by your needs – which is why we maintain close relationships with vehicle manufacturers, workshops, crafts and trades as well as industry experts. In order to gain valuable impetus for new product developments, we also rely on our HAZET technical advisors, who are on the road every day with their fully equipped HAZET demonstration vans and receive direct feedback from the market and users, often creating new products together via our product management and development departments.

When it comes to brainstorming, we are not just interested in developing a single product: we have the big picture in mind. As a full-range supplier, we offer high-quality tools and solutions that support workshops and tradespeople throughout their entire work process. This also applies to tool storage and occupational safety, for example. Saving time with new problem solvers helps the workshop to carry out repairs more cost-effectively and ultimately save the workshop customer money.

Phase 2: From concept to realisation

The focus here is on the detailed specification of the idea. This includes the technical specification, which defines the requirements that the product must fulfil. Naturally, the relevant norms and standards are also taken into account. We define all of this in a functional and requirement specification in order to create a clear guideline for further development. We at HAZET have a high level of quality and guarantee this as a DIN EN ISO 50001 certified company for our products.

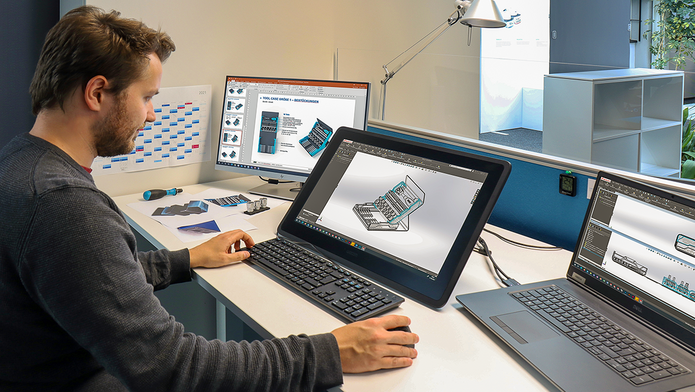

In the first step, we visualise the product and create initial technical drawings. These serve as the basis for the initial production of prototypes. The aim is to get a clear picture of what the product will ultimately look like and what technical features it will have.

Phase 3: The first prototype

Now the product is slowly taking shape. We create initial prototypes based on the concept.

With the functional prototypes in their luggage, our product managers or the developers themselves go to workshops, industrial or craft businesses. Through direct contact with potential users, we receive important feedback to further refine the prototypes. Initial samples show whether the product actually meets the requirements and works in real, practical applications. The feedback gained from this is very valuable to us and is naturally incorporated into the realisation of our products.

The highest standards and quality are already guaranteed during the production of such prototypes.

Thanks to our advanced production facilities on site, we have short distances and a close dialogue between product management, development and production. This allows us to make adjustments quickly and easily and continuously improve the product.

Phase 4: Industrialisation and validation – Putting our products through their paces

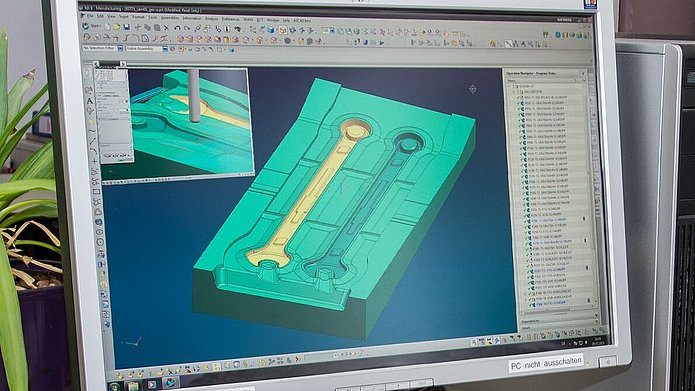

Technical details of the product are further elaborated and defined and described in corresponding documents, such as 3D CAD drawings, and stored in databases after technical approval.

These steps are carried out in close coordination with our production specialists to optimise the production processes and the optimum creation of the tools and production equipment required for production.

This enables us to guarantee efficient, high-quality production in large quantities and offer our customers the HAZET quality they have come to expect at a fair price.

Parallel to industrial production, our product has to go through the validation phase, where it is put through its paces.

In extensive laboratory tests, the product is subjected to legal and internal requirements as part of our quality management system.

![[Translate to english (en):] 639201058](/fileadmin/_processed_/8/4/csm_Phase_5_ebfbb93a58.jpg)

Phase 5: Series production

Once the product has passed the practical test, it is ready for series production.

When manufacturing our products, we at HAZET largely rely on in-house production and secure supply chains. Impressive proof of this is the in-house production rate of over 75% in our four plants. This enables us to guarantee precise control over the manufacturing process and the quality of our products. We focus on reliable and sustainable production.

Our tools have a long service life and good repairability. This is how we guarantee the quality of our products. If used correctly and cared for properly, they will last for generations to come!