Maintenance

Pneumatic tools require regular maintenance. You can find information on this and on the technical details in the relevant operating instructions.

Always note: insufficient lubrication of pneumatic tools leads to increased wear and the internal parts can corrode. This can lead to total failure of your device.

Pneumatic tools must therefore be lubricated during operation. This can be done by a few (1 to 2) drops in the air connection or, better still, by continuous lubrication using a maintenance unit (e.g. 9070-2, 9070-4 or 9070N-1). The oil is necessary for the lubrication of the engine, but also as corrosion protection. Our tip: hold a cloth in front of the air outlet after manual oiling. Excess oil is expelled via the exhaust air.

The lubricant on a hammer striking mechanism must be reapplied every six months if it is used on a daily basis. Note: Dosage with HAZET mini grease gun 2162M and cartridge 9300N-60. Please refer to the pictures for positioning and quantities.

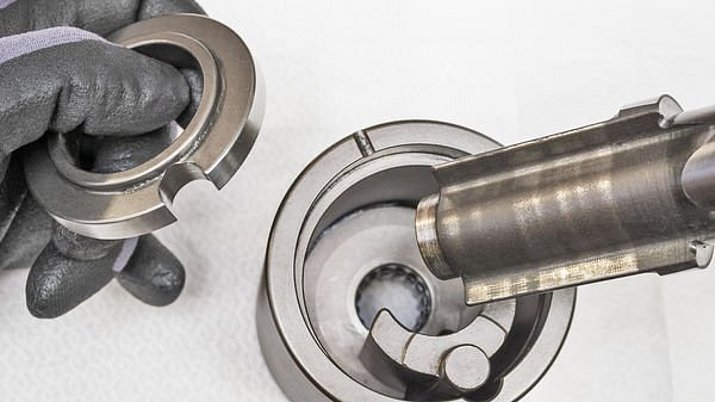

The lubricant on a direct striking mechanism must be reapplied every six months if it is used on a daily basis. Note: Dosage with HAZET mini grease gun 2162M and cartridge 9300N-60. Please refer to the pictures for positioning and quantity.

The oil on a pin clutch mechanism must be reapplied every six months if it is used on a daily basis. Only use special oil for pneumatic tools, e.g HAZET 9400-100 (100 ml) / 9400-1000 (1000 ml) and oiler 2160

Please refer to the pictures for quantities and positioning.

Repairs

Whatever the cause of your pneumatic tool's failure, we offer a comprehensive repair service, which you can send in directly to our Service Centre or via your specialist dealer.

Despite good lubrication, some components in the pneumatic tool are subject to wear. You can also carry out repairs yourself. You can find the right spare parts in our Spare Parts Shop.

Pneumatic tools

The performance of a pneumatic impact wrench is influenced by various parameters. A crucial factor is the air system to which the impact wrench is connected. As the air system differs from user to user, it is not possible to specify reliable torque values that apply to all air systems.

For professional workshop use, you need a large workshop compressor with a boiler volume of at least 200 litres

Smaller compressors are usually unable to supply the impact wrench with sufficient air on a permanent basis. You have to take frequent breaks during work so that the compressor can refill the air tank.

The working pressure is always measured directly at the device with flowing air.

The air connection nipples we supply usually have a sealant applied to the thread, and most air connection nipples also have conical threads. It is therefore usually not possible to screw in to the bottom of the thread. If the thread alone does not seal, you can help with a little Teflon tape, for example.

Air quality is described in ISO 8573-1. Accordingly, the air should be as dry as possible (no condensation), oiled (corrosion protection and lubrication) and free of foreign bodies. After the compressor, your system should therefore at least have a water separator, a fine filter and a lubricator.

Training offers

The maintenance and repair of pneumatic tools requires detailed expertise. We teach these skills in training courses that we offer at our modern "HAZET Welt" training centre or directly at our service centre in Remscheid. We can customise the content and scope of the training to suit your individual needs.

If required, simply ask us for the next dates.