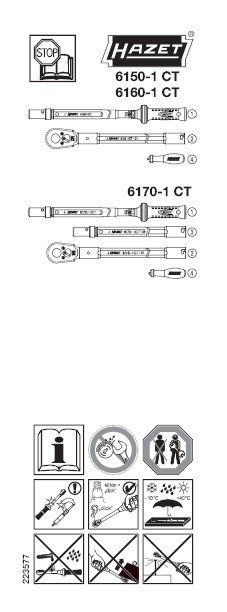

3⁄4″ Torque wrench with DAkkS calibration certificate ∙ 400 – 1000 Nm ∙ ±3%

Length: 1789 mm ∙ Torque range : 400 – 1000 Nm ∙ Accuracy: 3 % ∙ 3/4 inch square ∙ solid ∙ With DAkkS calibration certificate

Product information

- For the highest torque values

- Torque wrench with DAkkS calibration certificate

- Accuracy ± 3 % of the scale value (6170-1CT: ± 4 %) (in direction of actuation for right-hand tightening)

For left-hand tightening, use our torque wrenches with insert tool - For industrial climbers

- Application on wind turbines, dockyards, in the aviation industry and heavy industry, on commercial vehicles etc.

- Dismountable in 2 parts (6170-1CT 3 parts) with release tool

- Bag included for safe storage and for carrying or wearing on your back

- Fast screw tightening also with ratchet shaft alone. For torque tightening always use the complete wrench

- Safety:

- Haptic (close-gap release)

- Audible (“click” sound)

- 2-component handle for improved feel

- Simplified locking for adjusting the torque value

- Viewing window for visual checking of the locking

- 4 coloured coding rings (red, yellow, green, black) for markings in the case of personalisation or special workflows

- With calibration certificate and serial number

- Made in Germany

- No more turning back: Continuous long-term tests on the 5000 series and 6000 series of HAZET torque wrenches have demonstrated that turning them back to the smallest scale value is not required

DAkkS calibration certificate for the professional user, especially for:

- Aviation industry

- Automobile industry

- New-energy, wind turbines, offshore wind farms

- Petrochemical industry (oil/gas)

Documented traceability guarantees complete verifiability

SYSTEM 6000-1 CT industrial torque wrench ∙ 1 – 2000 Nm ∙ with reversible ratchet ∙ accuracy ± 2 / 4 %Calibration according to company standards

Variants

Technical Data

| Design ∙ Special feature | |

| Manual/impact operation |

|

| Tolerance | 3 % |

| Output |

|

| Tightening torque minimum | 400 Nm |

| Tightening torque maximum | 1000 Nm |

| Number of teeth | 32 teeth |

| Scale Graduation (Nm) | 5 Nm |

| Opening angle | 11.25 ° |

| Standard |

|

| Length | 1789 mm |

| Actuating force min.-max. kg | 24.2 – 61.0 |

| Head Width b | 77 mm |

| Head Thickness a | 36 mm |